SPE-11-8-092/A

05-Sep-11

Page 17 of 18

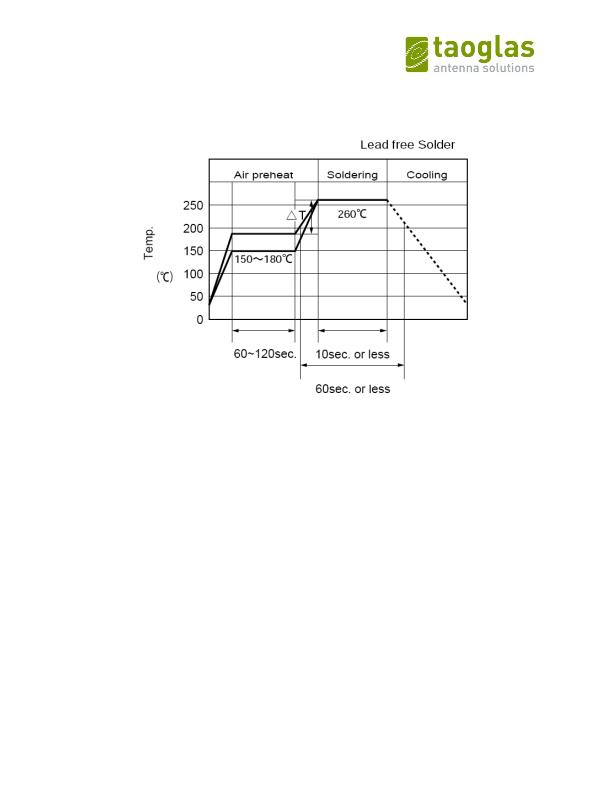

10.0 Recommended Reflow Temperature Profile

1. Time shown in the above figures is measured from the point when chip surface

reaches temperature.

2. Temperature difference in high temperature part should be within 110癈.

3. After soldering, do not force cool, allow the parts to cool gradually.

*General attention to soldering:

螲igh soldering temperatures and long soldering times can cause leaching of the

termination, decrease in adherence strength, and the change of characteristic may

occur.

?/DIV>

For soldering, please refer to the soldering curves above. However, please keep

exposure to temperatures exceeding 200癈 to under 50 seconds.

?/DIV>

Please use a mild flux (containing less than 0.2wt% Cl). Also, if the flux is water

soluble, be sure to wash thoroughly to remove any residue from the underside of

components that could affect resistance.

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

PA.15

ANT PIFA FIBREGLASS SMD

PA.22A

GSM DIELECTRIC PIFA ANTENNA

PBA-2030

ANTENNA PRECISION BICONICAL

PC.23.07.0100A

ANTENNA QUAD BAND CELL W/ CABLE

PC.23.09.0100A

ANTENNA GSM QUAD-BAND PCB

PC.24.07.0100A

ANTENNA GSM QUAD-BAND PCB

PC.24.09.0100A

ANTENNA QUAD BAND CELL W/ CABLE

PC11.07.0100A

ANTENNA DUAL-BAND PCB W/CABLE

相关代理商/技术参数

PA.15

功能描述:天线 2.4GHZ SMT FR4 LOOP ANT ONBRD ANT RoHS:否 制造商:Molex 技术类型:Cellular Antenna 频率: 带宽: 尺寸:106.7 mm L x 13 mm W

PA.22a

功能描述:天线 TRIBND CELL ANT 900/1800/1900MHZ

RoHS:否 制造商:Molex 技术类型:Cellular Antenna 频率: 带宽: 尺寸:106.7 mm L x 13 mm W

PA.25a

功能描述:天线 CELL PNTABND CERAM ONBRD ANT SMT

RoHS:否 制造商:Molex 技术类型:Cellular Antenna 频率: 带宽: 尺寸:106.7 mm L x 13 mm W

PA.26A

功能描述:ANAM LTE CERAMIC SMT ANTENNA 制造商:taoglas limited 系列:Anam 包装:剪切带(CT) 零件状态:在售 频率组:宽带 频率(中心/带):829MHz,2.2GHz 频率范围:698MHz ~ 960MHz,1.71GHz ~ 2.69GHz 天线类型:PCB 印制线 频带数:2 VSWR:3.5 回波损耗:- 增益:3.9dBi 功率 - 最大值:5W 特性:- 端接:焊接 侵入防护:- 安装类型:表面贴装 高度(最大值):0.236"(6.00mm) 应用:LTE 标准包装:1

PA.700.A

功能描述:天线 698-960,1710-2170MHZ W-CDMA LTE

RoHS:否 制造商:Molex 技术类型:Cellular Antenna 频率: 带宽: 尺寸:106.7 mm L x 13 mm W

PA.700.J

制造商:Taoglas 功能描述:ANTENNA PENTA BAND LTE/CELL/CDMA

PA.700A

制造商:Taoglas 功能描述:ANTENNA UNIT

PA.710.A

功能描述:天线 ULTRA WIDE-BAND LTE Cell CDMA SMT ANT

RoHS:否 制造商:Molex 技术类型:Cellular Antenna 频率: 带宽: 尺寸:106.7 mm L x 13 mm W